If you want to bring a composite component to series production, some problems can arise. A good example of this is a component with Nomex® Honeycomb as core material, which is produced using autoclave technology. Nomex® Honeycomb is a wonderful core material with many advantages, but like all composite materials and processes, it requires practical know-how for optimum results.

If you now only take the 3D data from the computer for your cutting templates or programs and do not adapt them for production, the result can be unsatisfactory and often involves rework. Depending on the certification of the component and the material and process released for repair, reworking can also be excluded in this case.

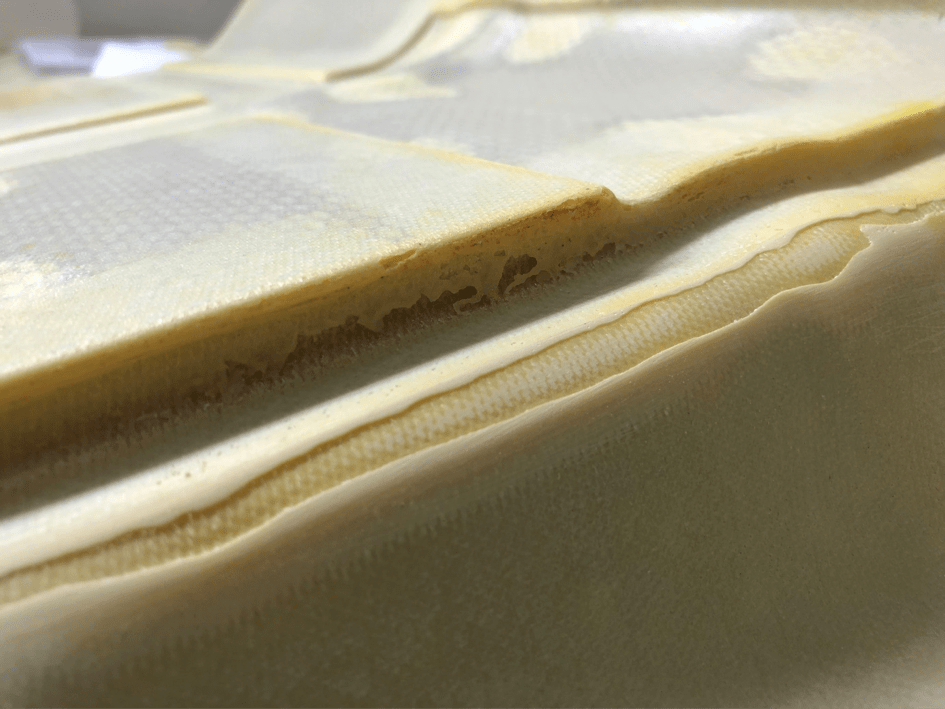

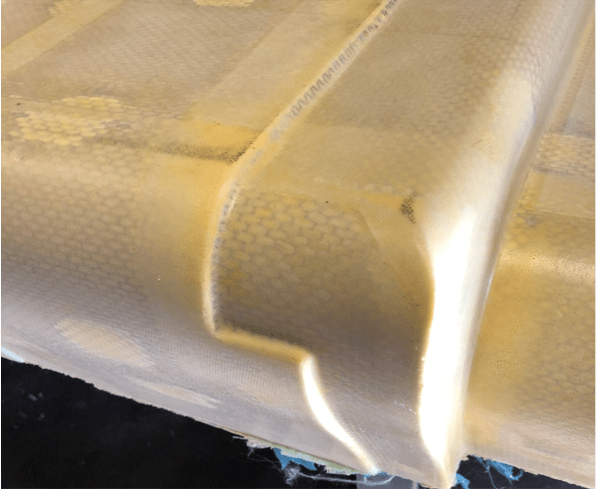

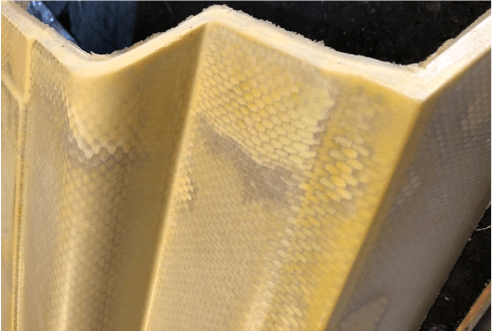

As we can see in the picture above, the pressure at these edges is not distributed in such a way that it produces an optimum result on the A-side of the component.

Background: When using Nomex® Honeycomb, it is not possible to use high pressure in the autoclave, as is usually the case with a purely monolithic component. Otherwise the material would collapse. This special feature has to be taken into account already in the design phase.

- The necessary considerations start with the correct size of the cut. What is the basis for a component with radius? From the tool surface, from the neutral phase of the core or from the core material top surface ?

- The fibre direction of the material must be considered.

- For joints at right-angled edges, the question arises which grain direction and which side overlap which ?

- Cut layout and deposit sequence must be defined.

- And then some more…

One strategy now would be to compensate for the lack of autoclave pressure by slightly pretensioning the material. Taking into account the fiber direction of the overstretched core material, this approach seems to be the most appropriate. Results as shown in the example pictures are then possible. However, it is important to ensure that the structure of the core is not crushed or destroyed. Only then can optimal results be achieved in series production. The example pictures show the components directly after demoulding, hence the still slight burr.

What is your current task?

Unfortunately, very often I am only called when there are already problems in production. The right planning pays off many times over when developing composite components. Let us discuss your project early on! You can reach me at +49 7161 988-4470 or at info@linge-composite.de